Harnessing

Harnessing

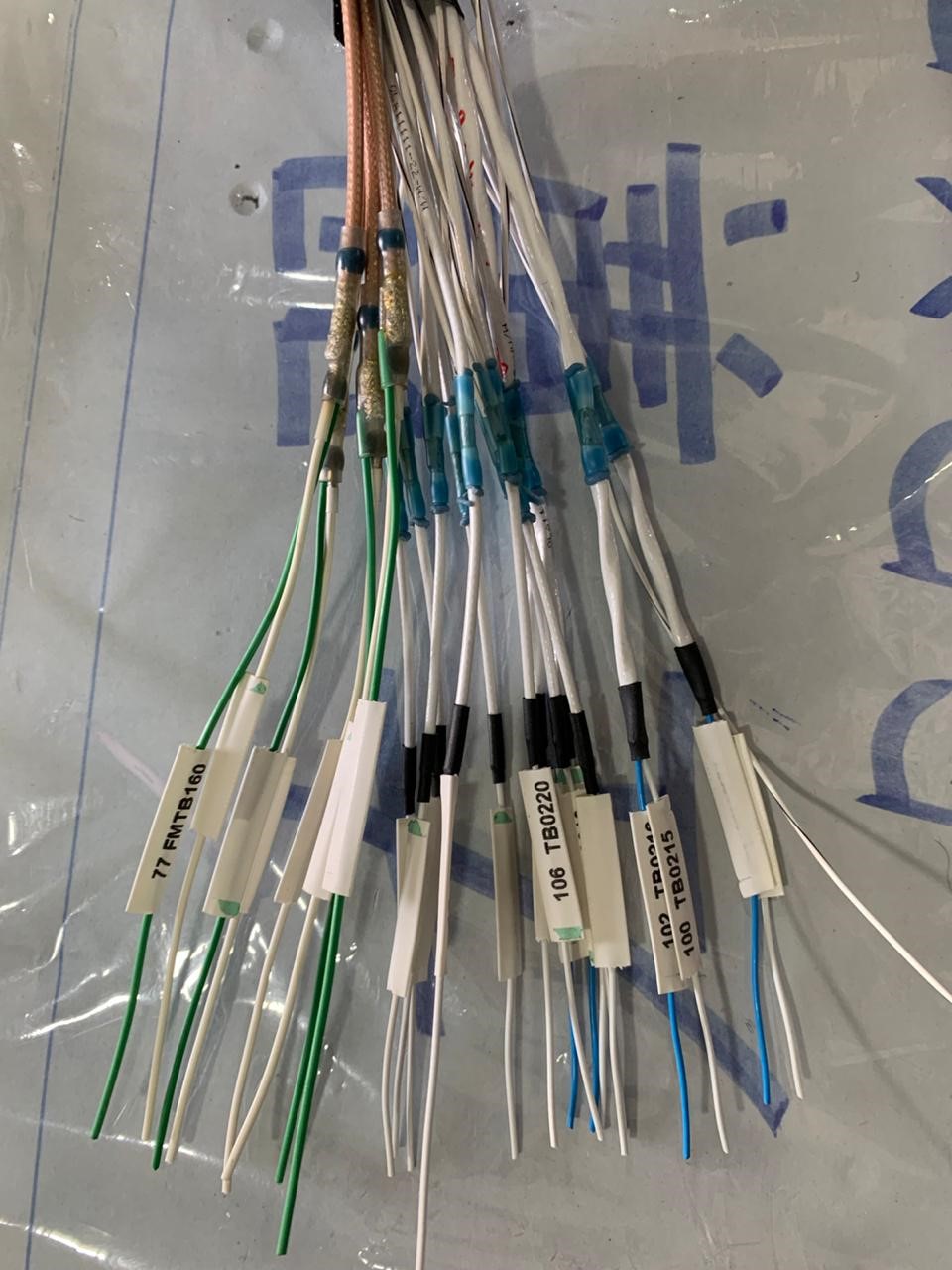

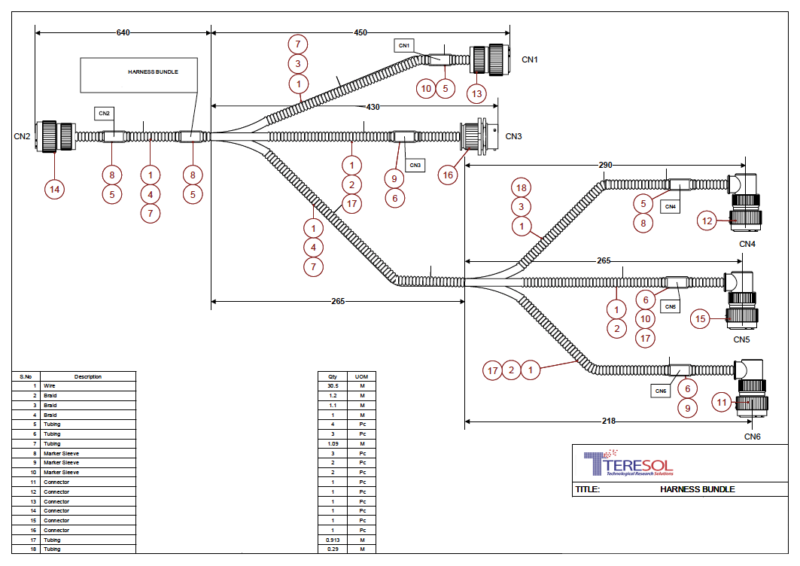

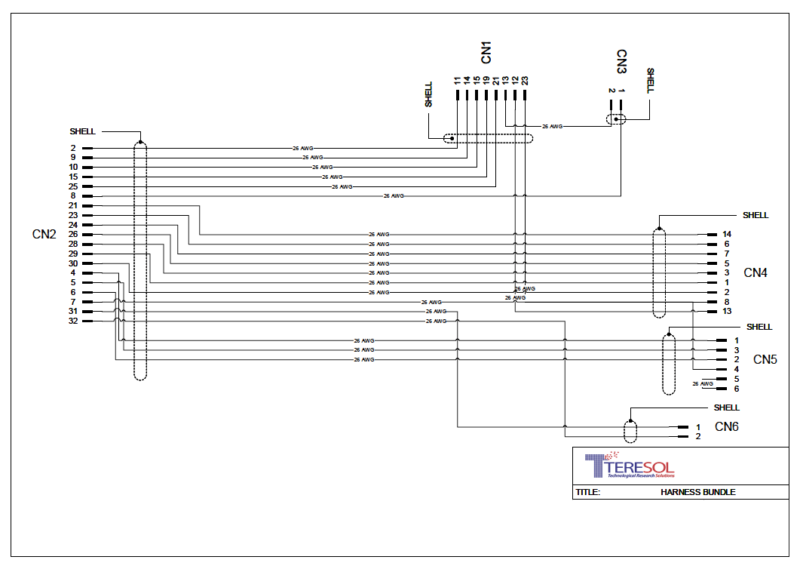

TeReSol has designed Form Fit and Functional replacement of existing harnesses of military APCs in adherence to international standard IPC/WHMA-A-620. Manual Identification of harness bundles was done and its mapping was achieved through latest CAD Tools

Product Details

OVERVIEW

TeReSol has expertise in delivering complex Form-Fit and Functional INTERCONNECT SOLUTIONS to the demanding specifications in compliance with MIL, IEA & IPC standards. We are a trusted provider of military cable assemblies and wire harnesses utilizing our broad capabilities and extensive portfolio to seamlessly provide best in class products. Offering services to prime defense contractors means we accept the responsibility to have strong quality and traceability protocols while complying with all documentation requirements, product configurations and process validations. This is made sure by investing in the best tools and people so that we have all of the design and manufacturing resources in house.

Block Diagram

SPECIFICATIONS

SALIENT FEATURES

- Expert in design and manufacture of Rectangular and Circular connectors based cable assemblies which meets severe environmental conditions, electromagnetic protection, secure data communication and reliable signal transmission

- Ruggedized Cable Assemblies and Harnesses with multi-branched construction connected with different type of contacts and connectors

- Lean engineering capability by taking an idea to conceptual design and then prototyping for meeting client needs & acceptance requirements and further provide reliable serial production

- Considering Electrical, Mechanical, Electromagnetic and Environmental constrains of system application for custom designed cable assemblies

- Committed to provide Interconnect Solutions through the quality processes meeting ISO, MIL, IEA and IPC standards and specifications.

STANDARDS & SPECIFICATIONS

TeReSol has been providing Interconnect Solutions based on standardized material specification and international testing standards.- MIL-DTL-38999/20F, MIL-DTL-83513F for Connectors.

- M22759 (SAE AS22759), Mil-W-16878 (M16878), Spec 44 for Insulated wires and shielded wires.

- A-A-59569D for Cable Metallic Braids.

- MIL-T-43435 (A-A-52082 Type III Teflon) , (A-A-52083 Type IV Glass) for- Lacing Tapes

- MIL-DTL-23053E, SAE‑AMS‑DTL‑23053 for Electrical Insulation Sleeving Heat Shrinks

- MIL-1-19166C for Polyamide 6.6 Cable Ties

- MIL-810G Compliance for Environmental Testing meeting specification as:-

- Temperature Test (Low / High) -30°C ~ +70°C for 24 Hrs. storage/operation

- Humidity Test +40°C with 95% RH for 24 Hrs.

- Vibration Test 2g acceleration, 20~30 Hz for 15 min.

- Shock Test 30g acceleration, 11ms half sine wave, 12 shocks

- Shock Ballistic Test 60g acceleration, 6ms half sine wave, 3 shocks

- Dust Test 6kg dust blowing at 0.5m/s for 15 min.

- IPC-A-620 Standard for Visual Quality Acceptability Requirements for Cable Assemblies and wire connections.

- EIA Standards for systematic compliance:-

| EIA-557 | Statistical Process Control Systems. |

| EIA-364-20 | Withstanding Voltage Test Procedure for Electrical Connectors, Sockets and Coaxial Contacts | EIA-364-21 | Insulation Resistance Test Procedures for Electrical Connectors, Sockets, and Coaxial Contacts |

| EIA-364-23 | Low Level Contact Resistance Test Procedure for Electrical Connectors and Sockets | EIA-364-26 | Salt Spray Test Procedure for Electrical Connectors, Contacts and Sockets |

| EIA-364-27 | Mechanical Shock (Specified Pulse) Test Procedure for Electrical Connectors | EIA-364-28 | Vibration Test Procedure for Electrical Connectors and Sockets |

| EIA-364-29 | Contact Retention Test Procedure for Electrical Connectors and Sockets | EIA-364-31 | Humidity Test Procedure for Electrical Connectors and Sockets |

| EIA-364-32 | Thermal Shock (Temperature Cycling) Test Procedure for Electrical Connectors and Sockets |

ADD-ONS

ADD-ONS